Customer Challenges:

The way NetSuite manages picking tickets natively, by printing a pick ticket per order, had slowed down the warehouse operations since the NetSuite go-live. The customer wanted a way to group orders for which items needed to be picked in the same zone within the warehouse in a consolidated “printable” list. They also wanted that list of orders to have barcodes compatible with code 39 and code 128 RF guns, as they wanted to use this list as a traveler sheet to expedite the picking process.

About the Customer:

Company: Missouri Star Quilt Co.

Location: Hamilton, Missouri

Industry: Retail, Consumer Business

Number of Users: 200

Number of Subsidiaries: 2

Solution:

It seems that the way NetSuite handles picking tickets is cause lot of delay in the warehouse as each order is printed on individual sheet and not grouped by picking zone.

Let the software do the heavy lifting

The trick here is to find an extremely creative solution leveraging one or a combination of out-of-the-box features. Going back to the problem. The goal was to group multiple picking tickets by warehouse bin on a single page. When I hear group transaction with a specific set of rules, I am thinking Saved Search. That would allow to group all orders pending fulfillment by bin where those items are located. That works!

There is so much you can do with Saved Search

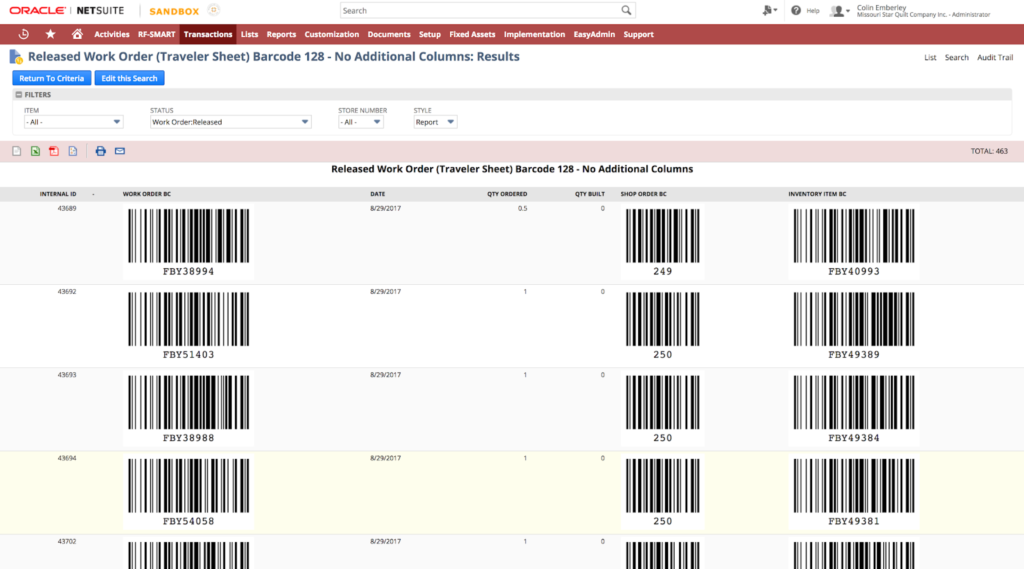

For Missouri Star, the next step was to ensure that whatever solution we came up with will be able to display scannable barcodes, as most of their warehouse operations are performed using RF guns. We built a saved search that inlined barcode for use with Code 39 and 128 RF guns. The saved search displayed on each line a scannable Order #, scannable work order # and scannable Item #. We arranged the column properly so it prints easily as a PDF document. We optimized the search to make it easy to pick component of assemblies.

We optimized the saved search to groups orders by picking zone (bins), eliminating the need for multiple travels to same location within the warehouse to picks orders with same item.

With this optimization project, Missouri Star is now able to ship orders faster. The grouping of orders for a specific picking zone has made their picking process much more effective. The inlined barcode allows them to expedite the picking process with literally no manual data entry

Most importantly, the multiple orders on one page have saved hundreds of trees since the solution was implemented.

Feature Setup and Technical Highlights:

Transaction Saved Search on pick tickets. Barcode formula….

Thierry Klesse, Senior NeSuite Solution Architect and Developer, designed and built this solution in collaboration with Colin Emberley, NetSuite Administrator at Missouri Star Quilt. Thierry has over 10 years experience with Enterprise Resource Systems (NetSuite, MS Dynamics SL, Movex Lawson), Database development (TSQL, DML, DDL), Javascript and .NET